一、方案组成

该动态真三轴(或者围压轴压)试验系统跟现有霍普金森压杆测试系统配套使用,主体包括四大部分,1)真三轴(或者围压轴压)主机加载系统,2)轴向加载伺服液压系统,3)数据测量与采集系统。在围压轴压或者真三轴加载,注水加温等多种环境耦合下的动态力学特性,得到动态应力、应变、应变速率、应变能、入射能、透射能、反射能、质点速度、高g值、加速度、试样升温、冲击韧性、位移、冲击力、单位体积吸能、轴压、围压、孔隙压力等数据。

1.真三轴(或者围压轴压)主机加载系统

整机采用一体式结构设计,加载框架采用高强度合金锻造成型,加载形式为两只油缸分别单方向加载,油缸分别安装在与框架垂直的两个平面上,其连接采用高强度螺栓连接,活塞前端与负荷传感器相连,负荷传感器前端与调整压块相连,构成示意图如图所示。其结构特定是高刚度加载框架,一体化结构设计,结构紧凑。因考虑与原霍普金森杆系统结合的情况,整机预留可安装导轨滑块的螺栓孔;真三轴(或者围压轴压)系统不包括导向装置、平台装置。

2.数据测量与采集系统

真三轴(或者围压轴压)加载系统是以三个液压控制系统;由多通道采集卡,液压源,控制阀,压力变送器,动态和静态应变传感器等组成;其中测量应力和应变采用静态数采系统完成,动态应力应变用现有动态应变仪及数采系统完成。测试时,将三个方向同时贴上双应变片,静态和动态分别进行采集和计算。应力部分直接由压力变送器采集。

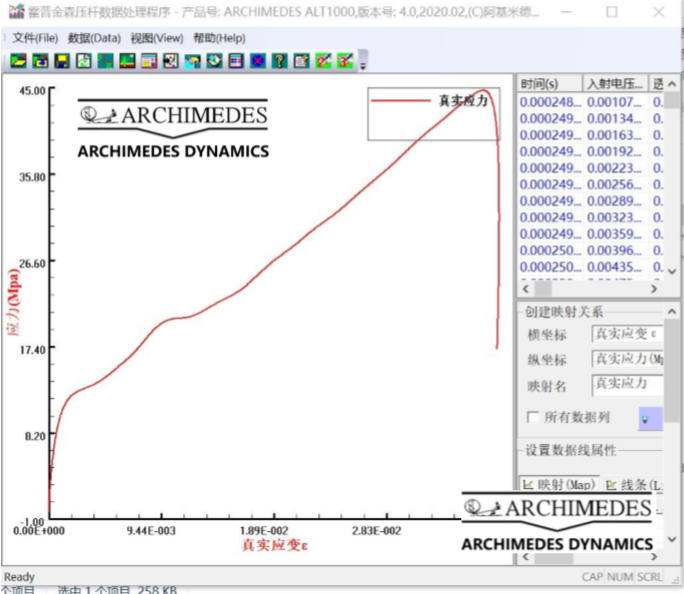

2.1 ALT1000型霍普金森压杆数据分析软件介绍:

ALT1000型霍普金森压杆数据分析软件专用于霍布金森杆实验的测试和分析。系统瞬态最高采样速率1MHz,每通道独立A/D模数转换器,外挂应变调理器完成1/4桥、半桥、全桥状态的应力应变测试和分析,对被测信号实时采集、实时显示、实时存储和实时分析,具备自动测试控制和数据波形分析处理功能,在围压轴压或者真三轴加载,注水加温,渗流等多种环境耦合下的动态力学特性,得到动态应力、应变、应变速率、应变能、入射能、透射能、反射能、冲击速度、加速度、位移、冲击力、高g值、试样升温、冲击韧性、单位体积吸能、轴压变化、围压变化、温度变化、岩石孔隙压力变化等数据。

3.岩石冲击过程的轴压变化,围压变化,温度变化,岩石孔隙压力变化:

冲击过程中轴压变化曲线

冲击过程中围压变化曲线

冲击过程中温度变化曲线

冲击过程中空隙压力变化曲线