一、动态硬度测试系统SHD-1000简介

硬度常用来表征材料抵抗压入变形的能力,反映材料的屈服强度、应变硬化能力或原子间结合键的强度等。传统的硬度测量技术有效反映了材料在准静态过程中的力学性能,但已有的研究表明大多数材料的塑性变形行为具有应变率相关性,多数金属在高应变率条件下屈服应力会增加;

而陶瓷的断裂韧性和断裂强度也会由于应变率效应而提高。因此静态硬度无法反映材料在诸如高速切削或高速碰撞时的高应变率行为。利用应力脉冲作用在与试样接触的刚性压头上,使试样表面形成动态压痕,进而测得材料的动态压痕硬度,简称动态硬度。动态硬度反映了材料抵抗压头动态压入变形的能力,其应变率达到10³~104/s,同时动态硬度测试快捷方便、试样无破坏。因此动态硬度是能够体现材料在复杂三向应力条件下高应变率行为的重要参数,有望成为一种新型的评价材料动态性能的手段。

动态硬度测试系统基于传统SHPB装置,根据单次应力脉冲加载原理建立了一套新型动态硬度测试系统,其结构如图1所示。系统由单次应力脉冲发生装置、波形整形器、压头、信号采集装置以及数据处理装置等组成。

二、动态硬度测试系统SHD-1000工作原理

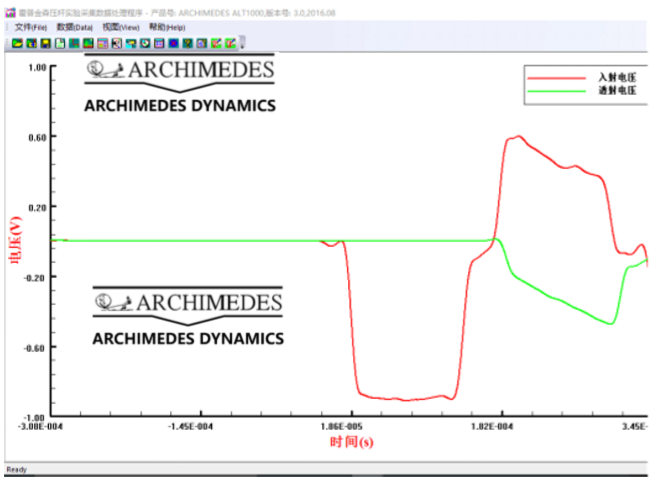

整套系统的核心部分是单次应力脉冲发生装置。它是由撞击杆、入射杆及其端部的法兰、套筒和质量作用块组成。当撞击杆撞击法兰产生压缩波同时向入射杆和套筒传播由于套筒和质量作用块紧邻,沿套筒传播的压缩波在套筒与质量作用块界反射成压缩波并沿套筒传播到法兰端面,在法兰端面反射为拉伸波向压头方向传播。撞击杆和套筒具有相同的声阻和长度,所以套筒中向左传播的压缩波和撞击杆左自由端反射的拉伸波同时到达法兰,拉伸波紧随压缩波向压头方向传播。压缩脉冲在压头端反射为拉伸波,向左传播到法兰与套筒界面时被套筒和质量作用块吸收,而不再反射为压缩波再次进入入射杆中,产生/动量陷阱效果,此后入射杆右行波只有拉伸波,确保了试样仅受一次压缩脉冲加载。图2(a),(b)分别是入射杆中应力波传播的理论波形和由应变片采集的实测波形,可见入射杆中往压头方向仅传播一次压缩波。为了调节加载应力脉冲的加载速率,滤去入射应力波中的高频部分,提高实验精度并保护金刚石压头,需要对加载脉冲进行整形。动态硬度测试系统中压头采用特制维氏金刚石压头,并通过螺钉等装置连接在入射杆端部。测试时,压头与试样一端无预应力接触,试样另一端与压电力传感器接触,压电力传感器输出的信号经电荷放大器放大后输入到电脑中并实时记录下来。

霍普金森拉杆数据处理软件可以自动识别透射波和反射波的跳动点和终止点,也可以人工识别,同时可以测试方形试样,可以计算试样的冲击应力应变,应变能,质点速度,反射能,透射能等各种数据,操作简单,使用方便,据当前行业一流水平。

霍普金森多功能拉杆设备主要由储气装置、发射与控制操纵系统、杆系与撞击杆、量测与分析系统、中心支撑部件、组合基础导轨、主动围压部分、单次加载装置、缓冲装置和辅助设备等组成。霍普金森多功能拉、拉杆设备是建立在统一高精度基准之下的一套专用试验设备。其中主要不同于其它设备的特殊部分分述如下:

发射系统:由储气室、发射体、操控模块、活塞、联接法兰、可快换变径炮管、支承座、反后座支架等组成。

杆件杆径:Φ10、Φ8

操作台:操控模块为独有结构,在发射体上安装,具有进气阀、储气室微调阀、减压阀、压力表、炮管底部排气阀、自动快速放(气)炮开关。可以自动操作撞击杆就位,撞击杆发射,采集冲击信号,导出冲击方波,得出应变率和应力等测试结果。

杆系与撞击杆: 材料为18Ni、弹簧钢、钛及其他高强度钢;金属材料均进行过热处理,所有杆件端面垂直度均可达到0.02以内,杆径和端面粗糙度达到Ra0.8以上。

中心支撑部件:由基座、开合上座、三向移动调整定位机构、高精度轴承、压盖、手动调整机构等构成。主要特点在统一基准导轨下可使不同直径杆系沿轴向运动为滚动摩擦,滑动轻快,自调整极其方便,最大优点受力合理使杆系工作寿命大大延长。

组合基准导轨:由型材导轨、地脚调节装置等拼合组成的一条整体导轨。使用专用技术,使导轨在安装好后,形成两个基 准:一个是侧基准,一个是水平基准,可使发射装置、杆系、支撑部件等在同一基准下工作,大大提高调试工作效 率。

三、动态硬度测试系统SHD-1000数据采集系统

1.设备功能介绍及主要技术指标:

ALT1000型超动态数据采集系统专用于霍布金森杆实验的测试和分析。系统瞬态最高采样速率40MHz,每通道独立A/D模数转换器,外挂应变调理器完成1/4桥、半桥、全桥状态的应力应变测试和分析,对被测信号实时采集、实时显示、实时存储和实时分析,具备自动测试控制和数据波形分析处理功能。

2.ALT1000型超动态数据采集系统:

- 12 Bits A/D分辨率

- 10KSPS-40MSPS采样率

- 4个并行采集通道

- 每通道8MSa缓冲存储器

- 丰富的触发功能

- 驱动程序支持WindowsXP Windows7

- ALT1000超动态数采系统是最先进的数据采集产品,最高采样率40MSPS,它具有高精度,低噪声,低失真和测试信号范围宽的特点。

- ALT1000超动态数采系统提供8路模拟信号输入并行采集测试通道,所有通道同时采样保持,各自进行独立的A/D转换,数据采集测量达12位A/D转换分辨率和最高40MSPS数据采样率。其高阻抗差分输入的每通道有独立的增益1-1600倍,可直接连接大多数传感器电压输出。

- ALT1000超动态数采系统有八个量程档±16V,±8V,±4V,±2V,±1V,±500mV,±250mV,±125mV,有一系统触发线和系统时钟线,可在多个采集器同时工作时选择系统触发和系统时钟之用,以便整个系统触发同步和以同一时钟进行采样,保持系统同步。

- ALT1000超动态数采系统具有软件触发、内触发、外触发和正负延迟多种触发功能。A/D转换率最高为40MSPS,向下按1、2、5分频;信号输入用BNC同轴电缆(可选用差分连接器)连接器输入。每通道采样的最大存贮深度为8MSa,可用软件随意设置采样长度。该系统配有系统驱动控制程序软件,在WindowsXP/7版本的操作平台下运行,控制面板完全是虚拟仪器软面板,图形化界面十分友好。

四.动态硬度测试系统SHD-1000软件简介

ALT1000的主操作界面

2.主要功能

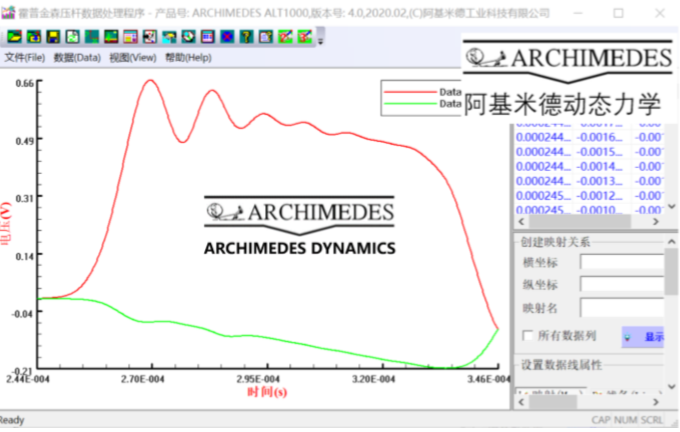

实验采集的数据主要包括时间、入射电压和透射电压。ALT1000程序对原始数据进行处理,主要功能有:

- 根据图像中的曲线图手动抓取入射波/透射波的起始位置,并分离出所需时间区间的所有数据。

- 根据特定的计算方法对原始数据进行分析并自动识别入射波/透射波的起始位置,并分离出所需时间区间的所有数据。

- 可实现移波操作,即当入射波和透射波的起始位置有偏差时,可对入射波或透射波的数据进行移动,以使两者的起始位置对齐。

- 针对有效时间区间的入射电压和透射电压,依据给定的实验参数计算相应的应变率、应力、应变能和高G值等参数。

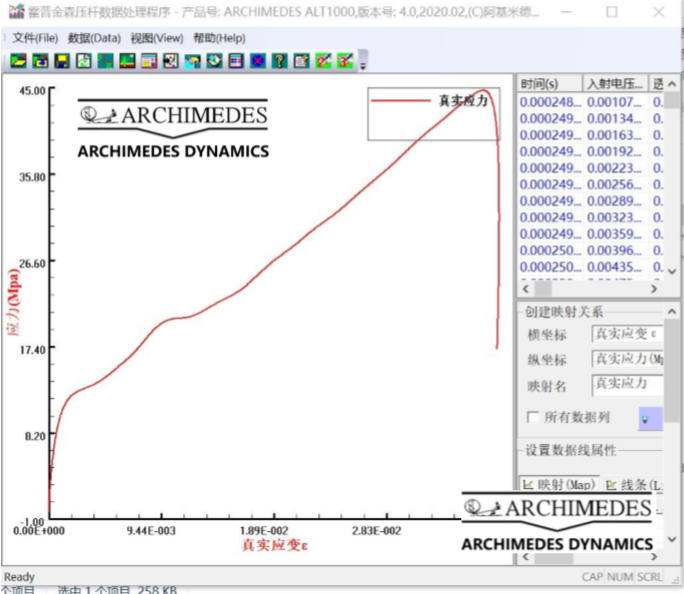

- 针对给定的数据列表,可按平面曲线的方式显示指定的映射关系。默认条件下,以时间数据表示横坐标值,其他数据列作为纵坐标值。

- 可对映射曲线的显示风格进行编辑,包括线型、线宽、颜色、显示间隔,节点符号的形状、大小、颜色、显示间隔等等。

- 可对坐标轴、注释框、图形边框等元素的风格进行编辑,包括坐标轴的名称、显示范围的数据区间,注释框的显示位置、是否隐藏边框,图形边框是否隐藏、网格辅助线是否显示等属性。

- 可实现图形/图像的缩放、移动、抓取、位图转换等功能。缩放和平移即改变曲线的显示范围,抓取即可以将点击图像获得对应的数值,位图转换即将变换为BMP格式的位图并输出。

自动截取波形并自动计算结果

应力应变曲线

五.测试结果:

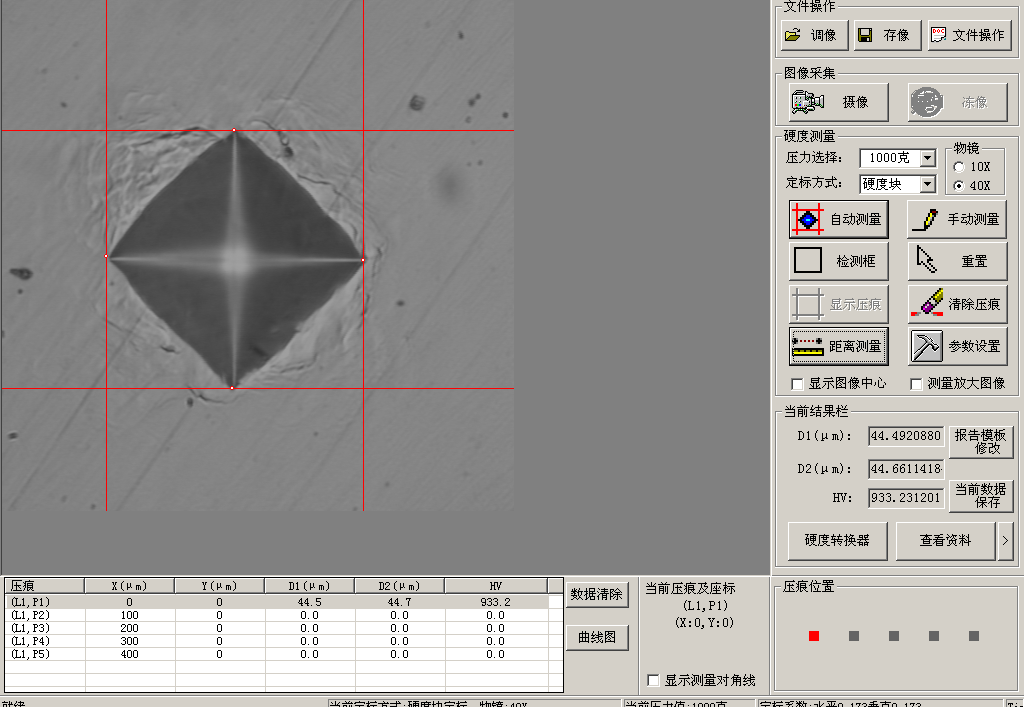

动态硬度测试方法静态维氏硬度反映了单位压痕表面积上的压力,物理意义清晰,故根据静态维氏测试原理及其测量标准,根据动态应力及应变,以及维氏压痕尺寸,可以得到动态维氏硬度计算结果。

将力值输入软件得出动态硬度结果