一、分离式霍普金森拉杆(SHTB)ALT1200简介

霍普金森杆是一种研究一维应力状态下材料动态力学性能的有效实验装置。自从 1949 年 Kolsky 发明它并用其研究一维应力状态下材料动态力学性能以来该实验装置已有很多改进,实验技术不断提高。该装置通过应力波的匀速传送对试样进行冲击,测试试样在受到动态冲击波冲击应力时的应变情况,并根据实验参数计算相应的动态应力、应变、应变速率、应变能、入射能、透射能、反射能、质点速度、加速度(高g值)、试样升温、断裂韧性,位移量、冲击力、入射应力应变、透射应力应变、反射应力应变等数据。

二、霍普金森拉杆(SHTB)ALT1200设备优越性能

ALT1200 采取柜体式结构设计,直接将发射系统及拉杆系统安装在两个操作台之间,所有零配件都安装在工作台内部,整齐美观,实用性很强。发射及控制系统安装在前操作台,操作人员在电脑前即可完成撞击杆发射,撞击杆回收数据处理等操作,非常方便。高温加热系统及同步气缸安装在后操作台,可以通过PID控制系统随意调整目标温度,高温炉外部带水冷系统,可以保证操作的安全。各个杆系通过不同直径的带轴承杆套可以安装在同一规格的支撑台上,可以随意更换压杆。同一系统也可以安装两套基座以适应不同直径的杆径,通过对杆及发射系统的系统调整,该设备可以冲击出经典的规则方波。

1. 可快速变换不同杆径:采用斜口压杆支座,在一台霍设上只需更换炮管就可方便实现各种霍杆试验,达到各种实验目的,可为用户节钱。

2.主体采用柜式结构加型钢轨道设计,实用性强,操作方便,外观符合现代工业美学理念。

3.可以拉杆和压杆共用一个主体,共用采集系统和气室发射系统,拉杆支架采用轴承支架,方便安装与滑动。

4.操作面板集成到炮管后的柜体上以保证操作安全,撞击杆可以自动发射,自动回位,采用双开关以避免误发射。

5.排除外部电磁干扰,同时防止采集系统误触发,发射控制系统采用气动控制系统。

6.数据采集软件可以随意选择波形的起点及终点,可以选取任意波段数据进行分析。

7. 数据处理软件自动识别透射波和反射波的起跳点,自动计算应力、应变、应变率、应变能、入射能、透射能、反射能、质点冲击速度,自动生成应力应变曲线,以及时间与上面各种参数的曲线,可以计算方形试样,以上功能可以现场演示。

8. 统一基准:由专有技术拼合成的分段组合式导轨,可任意接长或缩短,具有侧向和平面高精度统一基准,可使发射系统(包括各种炮管)、杆系(各种杆径)在同一基准下任一位置调试安装,极大节约调试时间,操作方便,提高试验精度。

9. 标准模块化:无论发射系统、中心支撑装置,还是导轨,全部采用标准模块化结构。无论你需要什么样的拉杆试验设备,都可通过数量增减而达到试验要求,易于推广。

10. 扩展性:系统具有很强的扩展性。可以加测速,高温,围压,三点弯,剪切等各种不同条件下的测试,可以在在导轨上增加一台辅助设备(高精度磨头变频动力驱动、短直线导轨副、杆件旋转动力机构等),即可解决长杆磨削问题;增加各种直径杆件的单次加载装置等试验项目不加什么就很容易实现;缓冲装置可移位等。

三、霍普金森拉杆(SHTB)ALT1200技术参数

霍普金森多功能拉杆设备主要由储气装置、发射与控制操纵系统、杆系与撞击杆、量测与分析系统、中心支撑部件、组合基础导轨、主动围压部分、单次加载装置、缓冲装置和辅助设备等组成。霍普金森多功能拉、拉杆设备是建立在统一高精度基准之下的一套专用试验设备。

- 应用范围:可对沙石土、混凝土、钢筋混凝土、金属和非金属泡沫材料、复合材料、高分子材料等进行较高应变率下的动态性能测试。也可对试样在不同外围约束力下进行动态性能测试。

- 霍普金森拉杆数据处理软件可以自动识别透射波和反射波的跳动点和终止点,也可以人工识别,同时可以测试方形试样,可以计算试样的冲击应力应变,应变能,质点速度,反射能,透射能等各种数据,操作简单,使用方便,据当前行业一流水平。

- 应变率:1000/s ~20000/s

- 加载方式:气动或则电磁加载

- 杆件杆径:Φ100、Φ80、Φ75、Φ70、Φ50、Φ37、Φ30、Φ20、Φ18、Φ16、Φ14.5、Φ12、

- Φ10、Φ8、Φ4等多种杆径可以共用一套主体。

- 杆系与撞击杆: 材料为18Ni、弹簧钢、钛及其他高强度钢;金属材料均进行过热处理,所有

- 杆件端面垂直度均可达到0.02以内,杆径和端面粗糙度达到Ra0.8以上。

- 可所使用的标准杆:4-100mm(一套设备可以同时配置2-3套不同规格的杆)

- 控制方式:双保险开关,气动控制

- 增压方法:空压机(高压氮气可选)

- 加热方式:PID温控,带水冷系统(可选)

- 冷却方式:液氮或者酒精(可选)

- 撞击杆测速:激光测速系统(可选)

- 围压及轴压:液压全自动加压系统(可选)

- 尾座缓冲:机械式或者液气联合缓冲

- 可以用于其他动态冲击力学的分析测试

- 符合国家标准:GBT 34108-2017 金属材料 高应变速率室温压缩试验方法

四.霍普金森拉杆(SHTB)ALT1200软件简介

1.操作界面(可自动识别计算波形)

霍普金森杆数据分析软件由阿基米德工业科技公司开发,功能非常强大,可以同时计算动态压缩、拉伸、扭转、弯曲、剪切等项目,得到动态应力、应变、应变速率、应变能、入射能、透射能、反射能、质点速度、加速度(高g值)、试样升温、断裂韧性,位移量、冲击力、入射应力应变、透射应力应变、反射应力应变等数据。

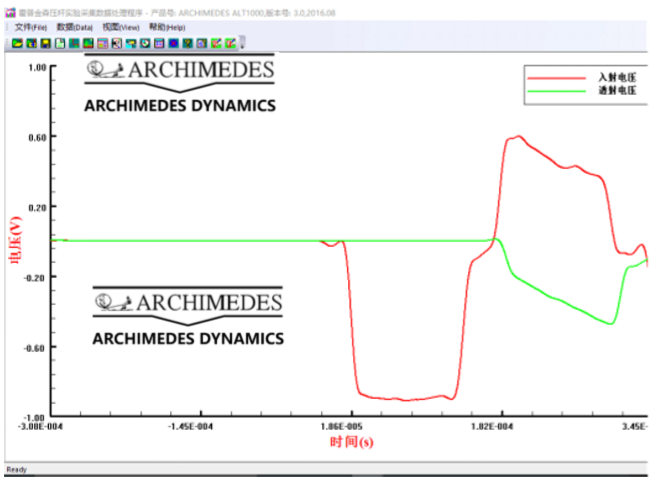

霍普金森(Hopkinson)杆实验采集的数据主要包括时间、入射电压和透射电压。数据分析程序对原始数据进行处理,主要功能有:

- 根据图像中的曲线图手动抓取入射波/透射波的起始位置,并分离出所需时间区间的所有数据。

- 根据特定的计算方法对原始数据进行分析并自动识别入射波/透射波的起始位置,并分离出所需时间区间的所有数据。

- 可实现移波操作,即当入射波和透射波的起始位置有偏差时,可对入射波或透射波的数据进行移动,以使两者的起始位置对齐。

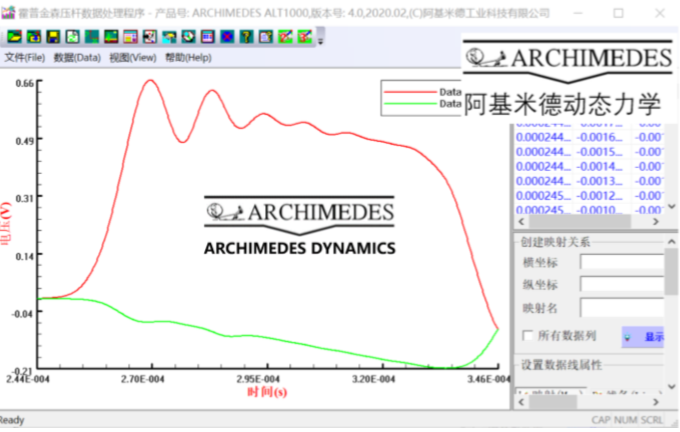

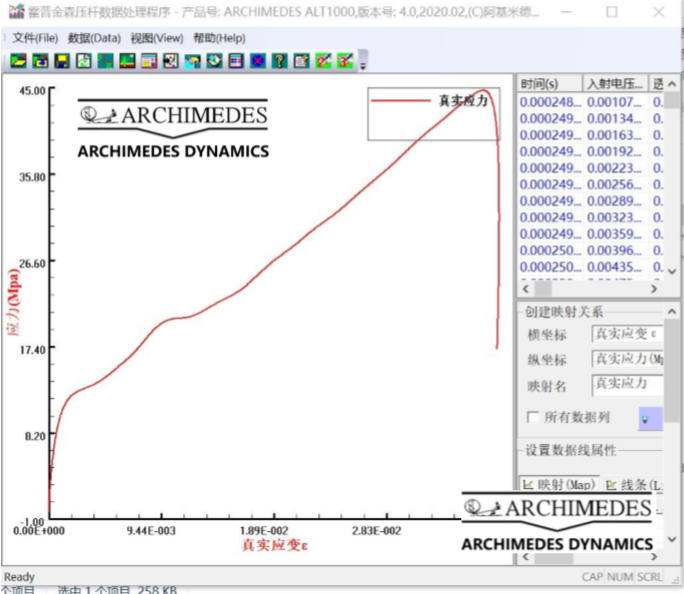

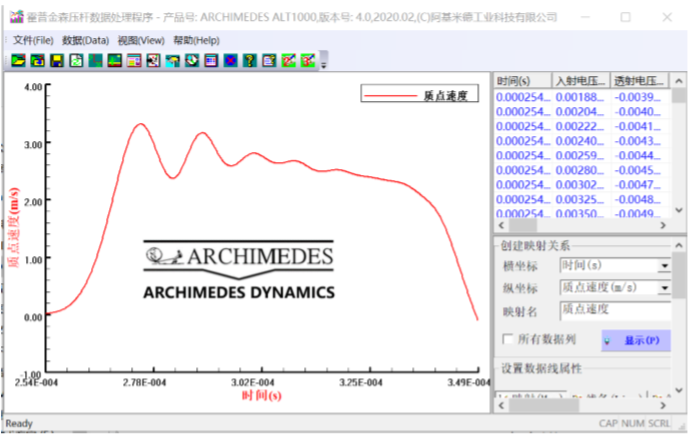

- 针对有效时间区间的入射电压和透射电压,依据给定的实验参数计算相应的应变率、应力、应变能和高G值等参数。

- 针对给定的数据列表,可按平面曲线的方式显示指定的映射关系。默认条件下,以时间数据表示横坐标值,其他数据列作为纵坐标值。

- 可对映射曲线的显示风格进行编辑,包括线型、线宽、颜色、显示间隔,节点符号的形状、大小、颜色、显示间隔等等。

- 可对坐标轴、注释框、图形边框等元素的风格进行编辑,包括坐标轴的名称、显示范围的数据区间,注释框的显示位置、是否隐藏边框,图形边框是否隐藏、网格辅助线是否显示等属性。

- 可实现图形/图像的缩放、移动、抓取、位图转换等功能。缩放和平移即改变曲线的显示范围,抓取即可以将点击图像获得对应的数值,位图转换即将变换为BMP格式的位图并输出。

- 符合国家标准:GBT 34108-2017 金属材料 高应变速率室温压缩试验方法

自动移波并截取波形并自动计算结果

动态应力应变曲线

应变速率1/s

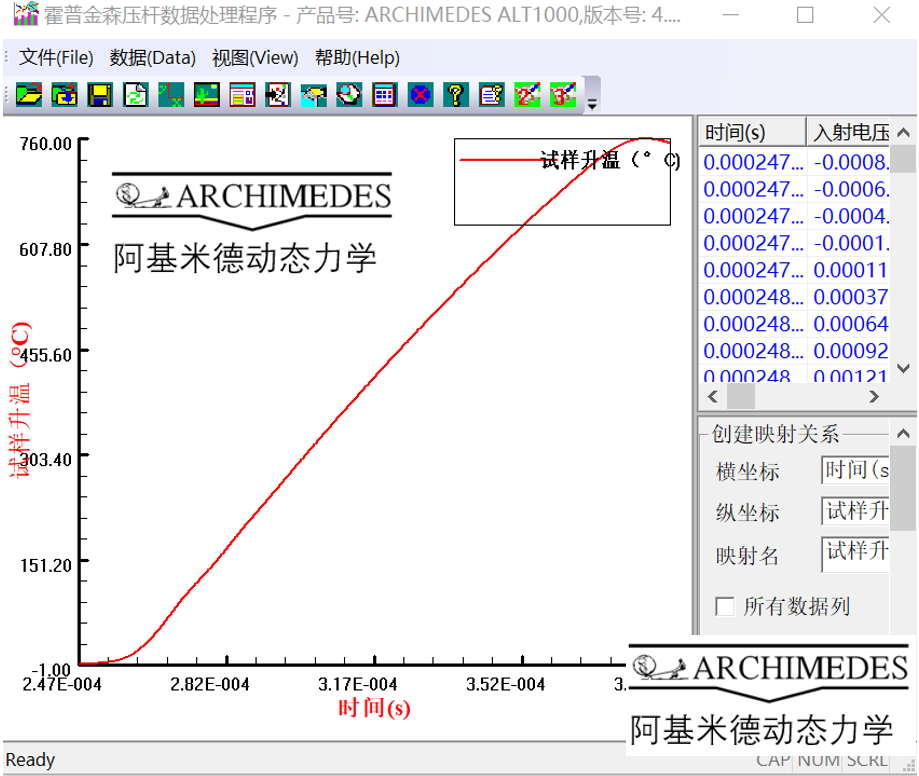

冲击试样瞬间升温(°C)

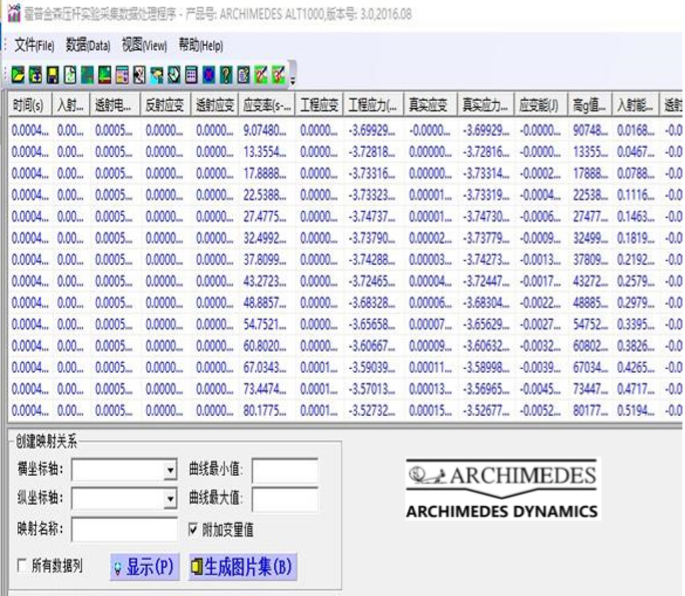

测试结果(动态应力、应变、应变速率、应变能、入射能、透射能、反射能、质点速度、加速度(高g值)、试样升温、断裂韧性,位移量、冲击力、轴压变化、围压变化、孔隙压力变化、入射应力应变、透射应力应变、反射应力应变等数据)

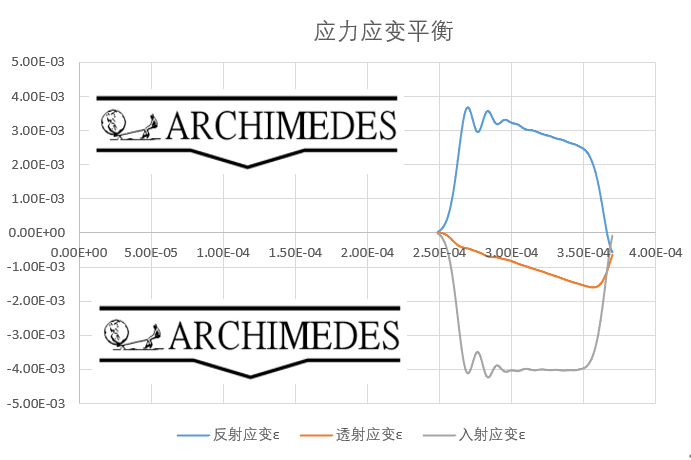

应力应变平衡

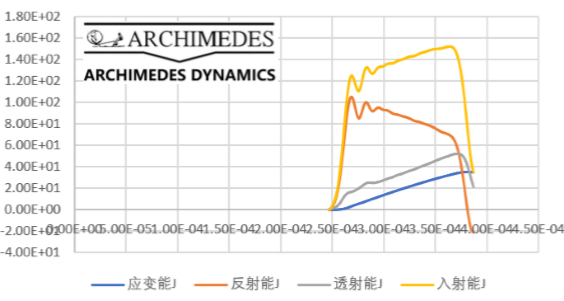

能量守恒(入射能=应变能+反射能+透射能)

五.具体工程应用:

可以进行不同杆径,不同围压,不同温度和压缩,弯曲,拉伸及剪切测试等,具体设计根据客户要求。一般有如下应用:

(1) 用同步组装系统进行高温、高应变率耦合作用下材料动态力学性能的测试;

(2) 在Hopkinson 拉杆技术中实现单脉冲加载及其在动态损伤力学中的应用;

(3) 用Hopkinson 拉杆加载三点弯曲试样测定材料的动态起裂韧性;

(4) 用Hopkinson 拉杆技术对高g值加速度传感器进行g 值校准;

(5) 快速落刀的应力应变测试

(6) 真三轴围压及假三轴围压时的霍普金森拉杆拉杆测试

(7)其他动态冲击力学方面的应力应变测试

六.设备图片及说明:

操作控制台及数据处理(专利设计:撞击杆自动发射回收系统)拉压杆一体机(带高低温测试)

- 动态应力应变测试软件著作权

用户现场效果图