一、动态光弹性法简介

动态光弹性法是实验应力分析的一种方法,用以研究弹性体动态应力和应力波传播规律。 采用这种方法,可以研究撞击应力和动态应力集中问题、地震波在不同介质中的传播规律、冲击波对地下结构物的作用,以及构件中裂纹的传播过程和止裂规律等。

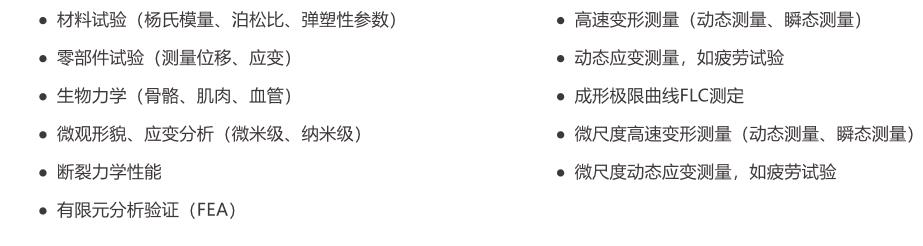

相比于以前采用的直接测量被研究物体的方法,我们现在可以使用高速摄像机以及相关的专业软件对其进行光学测量,包括测量材料的变形,位移和应变等信息。这种新技术被称之为数字图像相关技术(Digital Image Correlation,DIC),随着该技术的快速发展,已经在许多领域内取得了广泛的应用,例如航空航天、国防以及汽车行业等。

进1、通光口径:Φ500mm; 2.2、偏振片及刻度框:偏振片及刻度框,最小刻度 2.5 度,进口偏振片,厚度小于 3mm,单片透光率大于 99%, 双片消光率大于 95%,0360°旋转; 2.3、四分之一波片及刻度框:四分之一波片及刻度框, 进口四分之一波片,厚度小于 3mm,单片透光率大于 99%, 表面平整度λ/8,0360°旋转;

4、螺旋式加载架:螺旋式加载架,08000N,实现拉 压弯平顺加载并带有加载附件;结合同步旋转机构可自 由转动观察等差线和等倾线,带有力传感器和指示器, 更加精确了的控制加载力。应变式力传感器及指示器, 应变式力传感器及指示器,08000N,精度 0.5N; 2.5、光源照明系统:采用 LED 白光照明和 532nm 激光照 明两种方式,亮度满足高速摄像机拍照要求。

2.6、高速摄像机工作调节台:台面尺寸 200mm×120mm, 升降调节量±50mm,左右调节±12mm。

2.7、图像处理软件:

a. 四步彩色相移法;

b. 自动判别 第一主应力方向;

c. 相图去包裹处理;

d.全场剪应力的自动确定;e

. 应力分离的剪应力差法;

f.绘制主应力迹 线;

g.材料条纹值自动计算

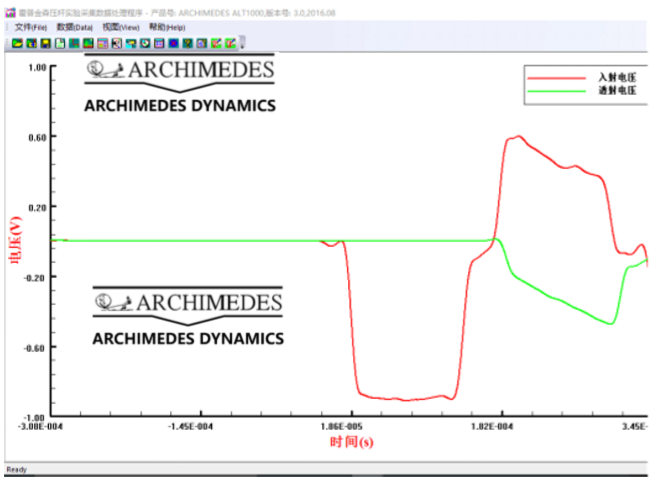

二、焦散线动态应力过程测量系统

将一束激光垂直照射在一块透明薄板试件上,如果试件承受载荷而引起厚度变化,则从试件的前后表面反射和折射的光线就会相互干涉而形成明亮条纹。如在试件的前面或后面一定距离处,在和试件平面平行的位置上放一幅屏幕,即可在屏幕上观察到一条清晰的曲线——焦散线。利用焦散线测量应变(或应力)奇异性的方法,称为焦散线法。

1、通光口径:Φ500mm

2、激光器:532nm,功率 0-200mW 连续可调

3、激光扩束镜:扩束夹角 10° 3.4、激光匀化器:匀化度≥98%

5、光轴高度 400mm,上下微调±30mm;

6、图像处理软件:具有焦散线去燥、增强,二值化, 细化,数值读取功能,并计算应力强度因子

三、超高速摄像机技术参数

采用独特的1280×800 CMOS传感器,满幅拍摄速率为7400帧/秒,最高拍摄速率可达到1000000帧/秒(可选);具有超高灵敏度(ISO):40000(黑白);10000(彩色)。20ns的时间精度,使其具有更高的帧速率、帧同步及曝光精度;395ns两次曝光最小时间间隔可满足PIV/PTV/LIF/DIC应用的需要,无图像滞后;EDR曝光控制可在1帧图像中设置2种曝光时间,有效避免眩光和爆炸过程中强光对成像的影响;最大存储容量256GB,满足长时间记录的需要;3G HD-SDI和标准HDMI视频输出,可连接模拟和数字监视器实时显示拍摄图像。

- 100万像素级像产品帧率:1280×800@7400帧/秒(7Gpx/s)

- 最高拍摄速率:680000帧/秒(标准);1000000帧/秒(可选)

- 最小曝光时间:1μs(标准);300ns(可选)

- 超高灵敏度(ISO):40000(黑白);10000(彩色)

- 内存容量:18GB/36GB/72GB

带围压的煤的动态光弹性法冲击测试

四、动态光弹性法高速摄像应力应变计算软件

超高速摄像(碳纤维冲击视频)