一、电液成形机总体介绍

电液成形是利用液体中强电流脉冲放电时产生的高能冲击波,是对金属毛坯进行加工的一种成形方法。由于成形时常以水作介质传递能量,故又称为电水成形。与爆炸成形相比,电液成形具有成形过程稳定、能量易于控制、操作方便,生产率高、便于实现机械化自动化生产等优点。但电液成形设备较复杂,其加工能力受到设备容量限制,因此,目前还仅限于中小型零件(Φ400mm以下)的中小批量生产。用电液成形方法可以对板材及管材进行的冲压加工有:拉深,胀形、校形、压印,冲孔等。

■ 采用PLC电脑控制,恒流充电;

■ 台式机和移动式两种机型可选;

■ 电液成形电压数字、指针表双重显示;450V~4000V(65系列6500V)间任意可调;

■ 电容量可切换、并有电容量显示;

■ 电液成形产量计数功能;

■ 输出脉冲电流显示功能

■ 多种安全保护功能。

二、电液成形机EHF20系统组成

2.1 控制柜

控制柜包括机柜、操作面板、充放电控制电路等。储能电容柜主要包括个的脉冲电容、变压器以及真空开关。设有电源开关、暂停、充电、放电、复位按钮及工作电压设定旋钮,装有电压表和各种指示灯来显示设备的工作状态信息传达显示方法,包括仪表显示、声响信息传达、触觉信息传达、符号传达等。操纵控制技术,包括机器的操纵装置、仪表控制装置、键盘技术等。安全保障技术,包括机器保险装置、防止人为的失误、事故控制方法、救援方法、安全措施等。

2.2储能电容柜

充电回路是电液成形机的重要环节,它必须可靠、高效地给储能电容充电。充电回路包括第一级直流电源、第二级开关充电电源、升压变压器、整流电路及相应保护电路。充电回路的作用是把交流电经过升压、整流等变换,转变成储能电容中的能量。这个回路由第一级直流电源、第二级半桥逆变电路、高压升压变压器、高压大电流整流硅堆、限流电阻、储能电容、采样电阻组成。充电回路的工作过程为进线的交流电,经过整流桥和滤波电容,得到左右的直流电压,该电压作为第二级半桥逆变电路的输入第二级逆变电路经由逆变,变压器输入的电压脉冲,高压变压器把电压升高到充电电压,经过整流后,通过限流电阻给电容充电。采样电阻上的采样电压送给比较电路板,与设定基准电压比较,到达预先设定的充电电压就停止充电。

显示及设置:

通过多圈精密电位器调节输出电压值,通过数显表显示工作电压、电流值。故障指示通过故障指示灯指示。

连接器:

输出高电压通过高压接头连接,安全可靠。

储能电容主要特点:

·功耗低,适宜于大功率、大电流、高耐压、高浪涌应用;

·具有最好的容量和体积性能比;

·随温度变化小,使用寿命长;

·反峰电压可达最高;

·高储能,耐高脉冲电流能力;

·自恢复特性好,性能稳定;

·低电感,低ESR;

·外壳材料为不锈钢或冷轧板、安装方便 。

2.3 电液成形部分

电液成形部分包括电极水箱及模具,可以根据不同用户需求订制。

三、电液成形工艺特点:

电液成形原理

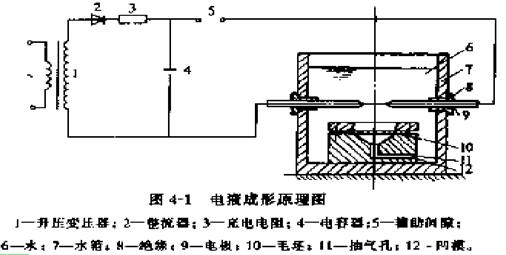

电液成形装置的基本回路如下图所示,其装置主要由充电回路和放电回路组成:

1、充电回路,它包括升压变压器、整流器和充电电用;

2、放电回路,它包括电容器、辅助开关和电极。

电液成形的电能释放有两种形式,即间隙放电和电阻爆丝放电。如将上图所示的电极之间用细金属丝联结起来,在电容器放电时,强大的脉冲电流会使金属丝迅速熔化并燕发成为高压气体,在介质中形成冲击波而使金属毛坯贴模成形,又称此为电爆成形。电爆成形时能量转换率高,皮形效果比间除放电时要大些,两电极之间的距离也可以大一些。

电液成形装置

电液成形可分为开式成形和闭式成形两种方式。一-般情况下,开式成形时的能量利用率仅为10%~20%,面闭式成形能提高能量利用率,可达30%。

电液成形所用电极可分为对向式、同轴式、平行式及活动式等多种形式,生产中常用对向式与同轴式。对向式电极结构简单,绝缘材料易于解决,但电极固有电感较大。同轴式电极固有电感小成形效率商,但电极结构复杂,对绝缘材料有较高要求。平行式电极具有易于调整与毛坯之间距离的优点,但在放电时受介质压力及电磁力的横向作用,必须注意结构上的强度问题。活动式电级的活动电极置于空气介质中,固定电极没没于液体介质中,活动电极借助于机械动作与固定电极接近,当两电极间距离减少至一定值时,发生放电现象。因此,可省掉放电回路中的辅助间隙,且不存在绝缘问题。但由于每次放电间隙距离存在差异,故引起压力及压力分布的不稳定,从面影响成形质量。

电液成形装置一般由水箱、放电电极和模具组成。水箱外壳和上董应具有足够的强度。为保证贴模精度,模具型腔内的空气应在放电前排除,所以成形装置中常附设抽真空系统。

四、技术参数:

项 目 |

规 格 |

能量(KJ) |

1 2.5 5 10 20 30 50 100 |

电压(KV) |

0.5 1 2 3 5 10 |

电容量 |

500~20000μF (可调整) |

最大电液成形直径 |

3/16’(4.8mm)

可电液成形铆钉材质:钢、铝合金、钛合金一般±5%,根据要求可以更小 |

输入电压 |

AC380V 50Hz;AC220V 50Hz |

输出电压 |

0.5 1 2 3 5 10

(各个量程范围内连续可调) |

开关 |

晶闸管/机械开关(可选) |

控制方式 |

PLC/按钮开关(可选) |

电压稳定度 |

≤1% |

|

|

负载稳定度 |

≤1% |

输出纹波 |

≤1% |

显示 |

具有电压、电流显示 |

冷却方式 |

风冷 |

使用环境温度宽 |

-40℃~+75℃ |

使用地点 |

工厂生产环境 |

等效串联电阻 |

ESR≤5mΩ |

保护措施 |

过压保护/过流保护/机械保护 |

测试系统(可选) |

应力应变测试系统及瞬间电流测试系统 |

电极 |

依据用户需求定制 |

可选附件 |

电液成形水箱或者机架 |