一、符合标准:

高温洛氏硬度试验系统HRN/T150可以测定从常温到高温的洛氏及表面洛氏硬度,最适合用来验明耐热金属材料、陶瓷制品等新材料的高温硬度。

For superficial and standard Rockwell hardness tests:

a. ISO 6508-1, Metallic materials – Rockwell hardness test – Part 1: Test method (scales A-B-C-D-E-F-G-H-K-N-T)

b. ISO 6508-2, Metallic materials – Rockwell hardness test – Part 2: Verification and calibration of testing machines (scales A-B-C-D-E-F-G-H-K-N-T)

c. ISO 6508-3, Metallic materials – Rockwell hardness test – Part 3: Calibration of reference blocks (scales A-B-C-D-E-F-G-H-K-N-T)

二、产品介绍:

高温硬度在诸多材料性能测试中无疑具有非常独特和唯一的地位.在动态力学领域,材料在高应变条件下瞬间升温,导致强度和硬度发生瞬间变化,所以温度和硬度之间的关系是研究材料损伤及失效的关键指标,高温硬度测试系统是动态力学研究的一款非常必要设备。 因为硬度测试是一个破坏性的试验,不同温度下材料硬度会随时变化,单一的测试方法无法得到同一试样在不同条件的精准硬度值,所以需要用不同方式去测量不同条件下的材料硬度,这就是我们高温硬度的存在动力。高温硬度测试是在较高的温度测量材料的硬度,高温硬度在多种情况都非常必要,如工具钢材料,耐磨涂层,如阀座和应用模具,它们都在高温下使用。高温硬度可以标识各种材料在高温下的不同的性能,具有巨大的实用性。由于室内温度变化相对硬度变化关联不大,它不能被用来评估高温性能。然而,材料的硬度,在温度变化显著的时候变化较大,如回火,磨损,腐蚀和热侵蚀的过程中,因此,压力和高温蠕变断裂性能问题,老化,滑动磨损,软化,蠕变变形等问题都有待用研究材料高温硬度来解决。通常情况下材料在高温情况下变软,可能导致磨损,这种粘着磨损和金属表面之间的材料相互损伤是工业中零件或设备失效的常见原因,不可以不认真研究。

该仪器可以测定从常温到高温的洛氏硬度,最适合用来验明耐热金属材料、陶瓷制品等新材料的高温硬度,共包含如下关键部件:

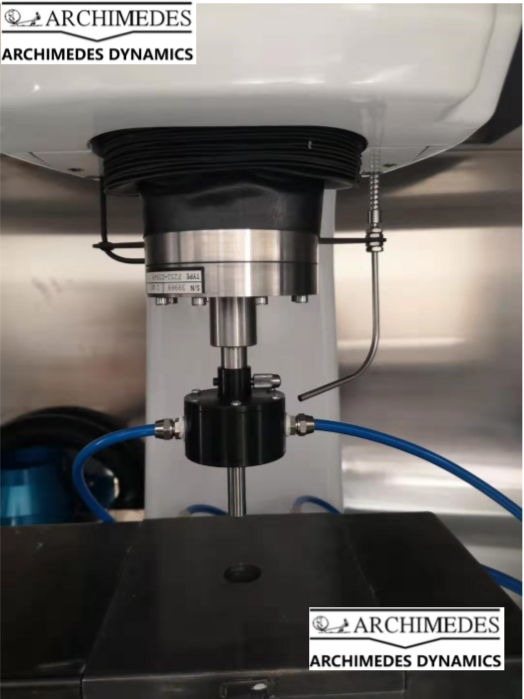

硬度计主机:数显双洛硬度计,配置专用测头,在高温环境中直接测试试样的洛氏和表面洛氏。高温炉的轴部是在保持炉内密封的同时使炉子自由升降,洛氏测头可以从炉外向炉内试样施加试验力。而且,从炉外施加的试验力和试验力的控制取决于外部的洛氏硬度计主机。

高温炉:高温炉是与轴部连接可以上下移动加热装置,是带有试样加热装置及试样的移动装置的密封性加热室,内有试样放置平台,加热丝,保温炉膛及惰性气体保护等装置。

加热环境控制系统:首先使高温炉内加热到所需温度,然后测定试样的硬度,测试过程中,试样放置在高温炉内保持高温状态。温控系统可以实现温度的任意升降和温度保持,惰性气体保护试样不被氧化,用高温硬度计专用测头从炉外施加洛氏硬度压力,完成全自动的洛氏硬度测试。

水冷系统:为了保护操作者安全,在密封良好的炉体内部充入恒温的循环水,保持高温炉外表面恒低温。

三、洛氏硬度计功能:

HRN/T150采用先进的微电可编程控制技术由全程控制硬度测试,其中硬度的测量完全由硬度计完成,无人为操作及人为误差影响。 LCD数显屏是机器的中心控制界面,参数设置,程序编制,数据显示,数据统计和存储等设定及操作都可以通过该操作界面完成,增加了人机对话的自动化,提高了工作效率。

设备加载系统采用封闭式砝码构架和人性化推杆实现试验力选择和自动加卸载的过程。消除传统通过旋钮选力而产生砝码构架的不稳定性。加载系统稳定性是机器工作稳定性的重要因素之一。

硬度标尺 |

A,B,C,D,E,F,G,H,K,L,M,P,R,S,V,15N,30N,45N,15T,30T,45T,15W,30W,45W,15X,30X,45X,15Y,30Y,45Y |

标尺转换 |

HB,HV,HR |

硬度值分辨率 |

0.1 HR |

初试验力 |

3kgs,10kgs |

主试验力 |

15,30,45,60,100,150kgs |

初试验力加载 |

手动 |

主试验力加载 |

全自动 |

数据输出 |

USB2接口,内置打印机 |

LCD触摸屏 |

菜单选择,硬度值显示,数据统计,存储,参数设置等 |

电源 |

110/220伏,50-60赫兹 |

机器尺寸 |

920x395x680毫米 |

机器重量 |

140公斤 |

四,高温炉及温度控制系统:

高温炉采用目前世界上最先进的全纤维真空压制炉膛,具有节能、美观、使用寿命长和安装维修方便的特点;温度控制系统采用人工智能控制、具有控温精度高,性能稳定可靠等优点。炉体及炉盖采用双层不锈钢的坚固结构,中空通流动水,降温效果良好,外壳温度25°C恒温,以保护操作者安全。

高温炉采用高性能内置式加热体,升温速度快、调节灵敏、精度高,温度稳定,温度工作上线有较大扩展,采用PID温度控制仪,性能可靠、使用方便。 温度可任意编程升降调节。

高温炉中心跟硬度计主轴刚性连接,高温炉炉膛内部镶嵌有加热炉丝,炉膛中心有耐高温水平物台,物台直径40mm,可以放置与物台大小相当的试样进行高温硬度测试。