电磁脉冲高速试验机,采用电磁脉冲能量对试样瞬间加载,测试其高速加载时的应力应变。包括电源、底座、固定设置在底座上两侧的两个支撑架、两端分别固定设置在两个支撑架的顶部的横梁、沿竖直方向固定设置在横梁与底座之间的磁力线圈拉伸装置以及设置在两个支撑架上的驱动装置,磁力线圈拉伸装置包括竖直方向固定驱动装置上的固定管、穿设于固定管的磁性拉杆、固定设置在磁性线圈拉杆下端的上夹具以及对应上夹具固定设置在底座上的下夹具,固定管的内壁设置有线圈,驱动装置可将磁力线圈拉伸装置固定设置在预设的高度,电源对固定管内的线圈供电,可以使线圈瞬间产生磁场,使金属拉杆受到磁力作用在固定管内上下移动,使上夹具和下夹具能够将样品拉伸作用,和现有技术相比,通过产生磁场对金属拉杆施加磁场力使磁性拉杆能够产生较快的加速度。通过在拉杆和下面底座上的拉杆贴应变片,采集拉杆受力及应变情况,测试出试样的应力应变特性。

HUT-M120型超动态数据采集系统功能介绍:

HUT-M120型超动态数据采集系统专用于电磁脉冲高速试验机的测试和分析。系统瞬态最高采样速率1MHz,每通道独立A/D模数转换器,外挂应变调理器完成1/4桥、半桥、全桥状态的应力应变测试和分析,对被测信号实时采集、实时显示、实时存储和实时分析,具备自动测试控制和数据波形分析处理功能。

HUT-M120型超动态数据采集系统:

-

12 Bits A/D分辨率

-

10KSPS-40MSPS采样率

-

4个并行采集通道

-

每通道8MSa缓冲存储器

-

丰富的触发功能

-

驱动程序支持WindowsXP Windows7

-

ALT1000超动态数采系统是最先进的数据采集产品,最高采样率40MSPS,它具有高精度,低噪声,低失真和测试信号范围宽的特点。

-

ALT1000超动态数采系统提供8路模拟信号输入并行采集测试通道,所有通道同时采样保持,各自进行独立的A/D转换,数据采集测量达12位A/D转换分辨率和最高40MSPS数据采样率。其高阻抗差分输入的每通道有独立的增益1-1600倍,可直接连接大多数传感器电压输出。

-

ALT1000超动态数采系统有八个量程档±16V,±8V,±4V,±2V,±1V,±500mV,±250mV,±125mV,有一系统触发线和系统时钟线,可在多个采集器同时工作时选择系统触发和系统时钟之用,以便整个系统触发同步和以同一时钟进行采样,保持系统同步。

-

ALT1000超动态数采系统具有软件触发、内触发、外触发和正负延迟多种触发功能。A/D转换率最高为40MSPS,向下按1、2、5分频;信号输入用BNC同轴电缆(可选用差分连接器)连接器输入。每通道采样的最大存贮深度为8MSa,可用软件随意设置采样长度。该系统配有系统驱动控制程序软件,在WindowsXP/7版本的操作平台下运行,控制面板完全是虚拟仪器软面板,图形化界面十分友好。

-

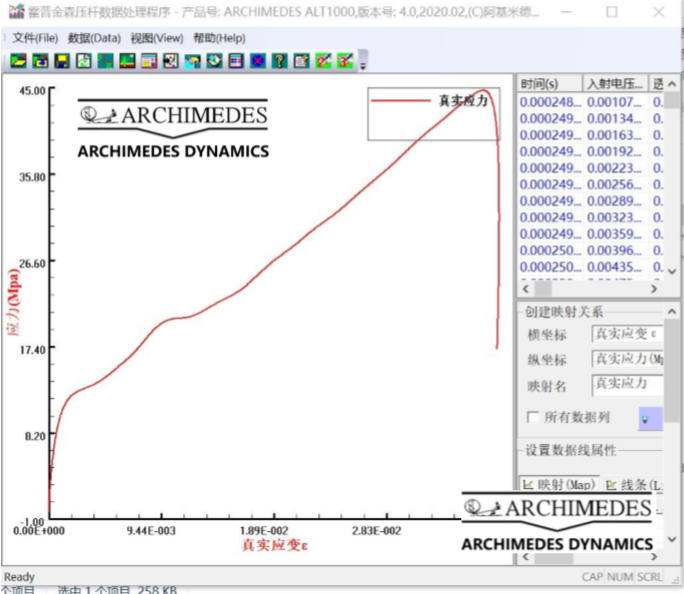

该软件在电磁脉冲高速试验机采集的数据基础上,对应力波进行识别和分离,并根据实验参数计算相应的应变率、应力、应变能和高G值等参数。此外,该软件平台提供了平面曲线的显示和编辑功能,原始数据和计算数据可通过图形、图像方式显示和输出。

-

实现应变率20-500s-1

-

实现的工程应变:0 - 50%(与试样几何尺寸和材料有关)

-

横梁测试最大宽度值:420 mm

-

衡量移动最大位移量:1100 mm

-

软件接口USB 2.0 - Interface or LAN

-

数据传输速率50Hz / 400Hz (配单独板卡)

-

控制器预留两个板卡插槽可连接模拟/数字输入/输出接口,用于测量载荷、应力等指标,外接装置输入为+/-10V输入电压:AC220V 50Hz;

-

输出电压:0 ~ 10KVDC 连续可调;

-

电源输出功率:5000W;

-

电压稳定度:≤1%;

-

负载稳定度:≤1%;

-

输出纹波:≤1%;

-

显示:具有电压、电流显示;

-

冷却方式:风冷。

-

电容容量范围:C=12000μF;

-

容量偏差:一般±5%,根据要求可以更小;

-

电容额定电压:Un=10KV;

-

等效串联电阻:ESR≤5mΩ

-

反峰电压可达80%以上;

-

充放电次数:可达2,000,000次;

-

损耗角正切:tgδ≤0.002(100Hz);

-

使用环境温度宽:-40℃~+75℃;