1、 Brief intbaruction of split Hopkinson torsion bar

ALT1600 Hopkinson bar is an effective experimental device to study the dynamic mechanical properties of materials under one-dimensional stress. Since Kolsky invented it in 1949 and used it to study the dynamic mechanical properties of materials under one-dimensional stress state, the experimental device has been improved a lot and the experimental technology has been improved continuously. The device tests the strain of the specimen when it is impacted by dynamic shock wave through the uniform transmission of stress wave. According to the experimental parameters, it can calculate the dynamic shear stress, shear strain, shear strain rate, strain energy, incident energy, transmission energy, reflection energy and other data. Conform to national standard: GBT 329671-2016 high strain rate torsion test for metal materials. Application: it can test dynamic properties of sand, concrete, reinforced concrete, metal and non-metallic foam, composite and polymer materials at high strain rates. It can also be used to test the dynamic performance of the sample under different peripheral constraints. Loading mode: pneumatic or electromagnetic Maximum diameter of sample: 50mm Strain rate: 1000 / S ~ 20000 / S Standard pole to be used: 4-100mm (one set of equipment can be equipped with 2-3 sets of poles of different specifications at the same time) Control mode: double safety switch, pneumatic control Pressurization method: air compressor (high pressure nitrogen optional) Heating mode: PID temperature control, with water cooling system (optional) Cooling method: liquid nitrogen or alcohol (optional) Bullet speed measurement: laser speed measurement system (optional) Confining pressure and axial pressure: hydraulic full-automatic pressure system (optional) Tailstock buffer: mechanical or liquid gas combined buffer It can be used in the analysis and test of other dynamic impact mechanics 2、 Superior performance of Hopkinson torsion bar alt1600 Alt1600 adopts the cabinet structure design, and directly installs the launch system and torsion bar system between two operating consoles. All the spare parts are installed inside the workbench, which is neat, beautiful and practical. The launch and control system is installed in the front console, the operator can complete the operation of bullet launch and bullet recovery data processing in front of the computer, which is very convenient. The high temperature heating system and synchronous cylinder are installed in the rear console, and the target temperature can be adjusted at will through the PID control system. The water cooling system is installed outside the high temperature furnace to ensure the safety of operation. Each bar system can be installed on the same specification support platform through different diameter bar sleeve with bearing, and the pressing bar can be replaced at will. The same system can also be equipped with two sets of bases to adapt to the bar diameter of different diameters. Through the system adjustment of the bar and the launching system, the equipment can impact the classic regular square wave. 1. It can change the diameter of different bars quickly: adopt the diagonal compression bar support, in a Huo set, it is convenient to realize all kinds of Huo bar tests by changing the barrel, achieve all kinds of experimental purposes, and save money for users. 2. The main body is designed with cabinet structure and profile steel track, which has strong practicability, convenient operation and appearance in line with modern industrial aesthetic concept. 3. The torsion bar and pressure bar can share a main body, a collection system and a gas chamber emission system. The torsion bar bracket adopts a bearing bracket, which is convenient for installation and sliding. 4. The operation panel is integrated on the cabinet behind the gun barrel to ensure the operation safety. The impact bar can be automatically launched and returned to its original position. Double opening and closing are adopted to avoid misfiring. 5. Eliminate the external electromagnetic interference and prevent the acquisition system from triggering by mistake. The launch control system adopts pneumatic control system. 6. The data acquisition software can select the start and end points of the waveform at will, and can select any band data for analysis. 7. The data processing software automatically identifies the take-off points of the transmitted and reflected waves, automatically calculates the stress, strain, strain rate, strain energy, incident energy, transmission energy, reflection energy, particle impact speed, automatically generates the stress-strain curve, as well as the curve of time and above parameters, and can calculate the square sample. The above functions can be demonstrated on site. 8. Unified benchmark: the segmented combined guide rail assembled by proprietary technology can be arbitrarily lengthened or shortened, with high-precision horizontal and plane unified benchmark, which can make the launching system (including various gun tubes) and bar system (various bar diameters) debug and install at any position under the same benchmark, greatly saving debugging time, convenient operation and improving test accuracy. 9. Standard modularity: no matter the launch system, central support device or guide rail, all adopt standard modular structure. No matter what kind of torsion bar test equipment you need, you can meet the test requirements by increasing or decreasing the number, which is easy to promote. 10. Expansibility: the system has strong expansibility. It can be tested under various conditions, such as speed measurement, high temperature, confining pressure, three-point bending, shearing, etc., and an auxiliary equipment (high-precision grinding head frequency conversion power drive, short linear guide pair, bar rotating power mechanism, etc.) can be added to the guide rail to solve the problem of long bar grinding; it is easy to be realized without adding any test items, such as single loading device for various diameter bars Now, the buffer device can be shifted, etc. 11. Meet the national standard: GBT 329671-2016 high strain rate torsion test for metal materials.

4.Brief intbaruction of Hopkinson torsion bar alt1600 software

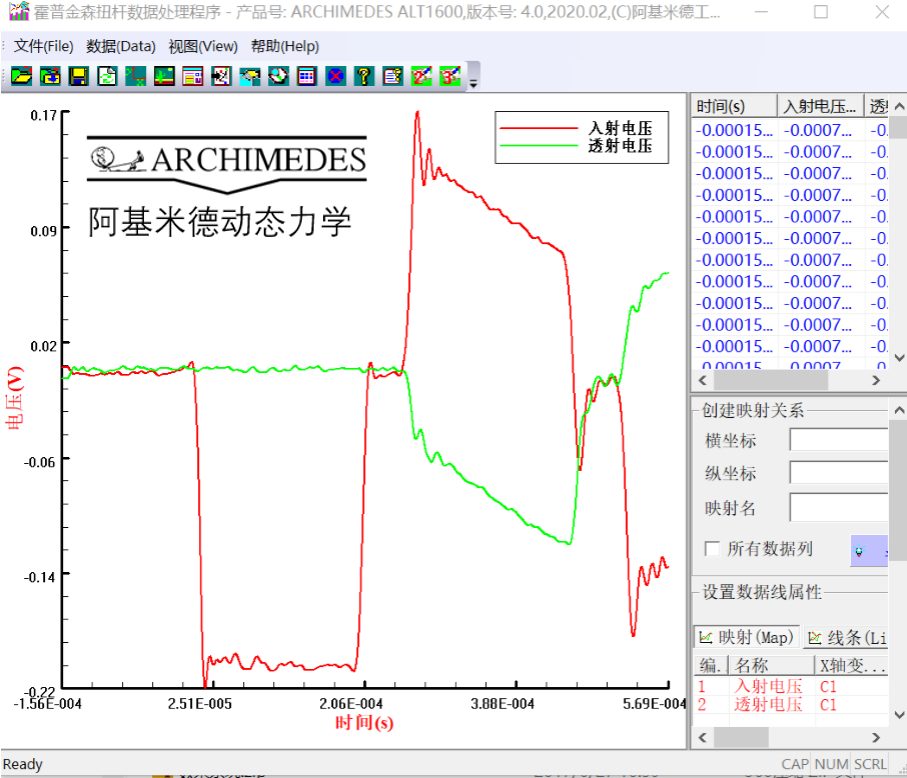

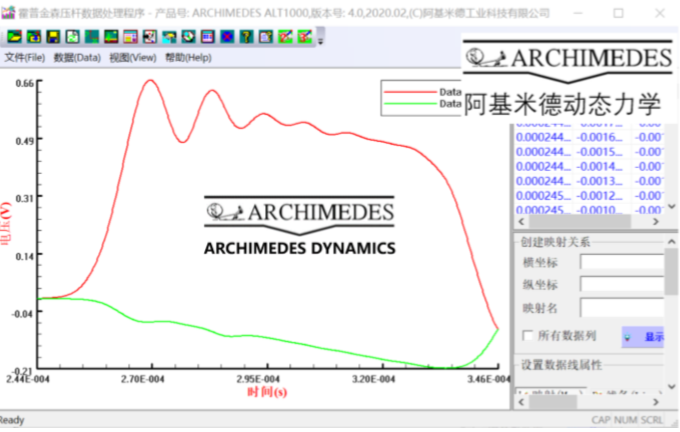

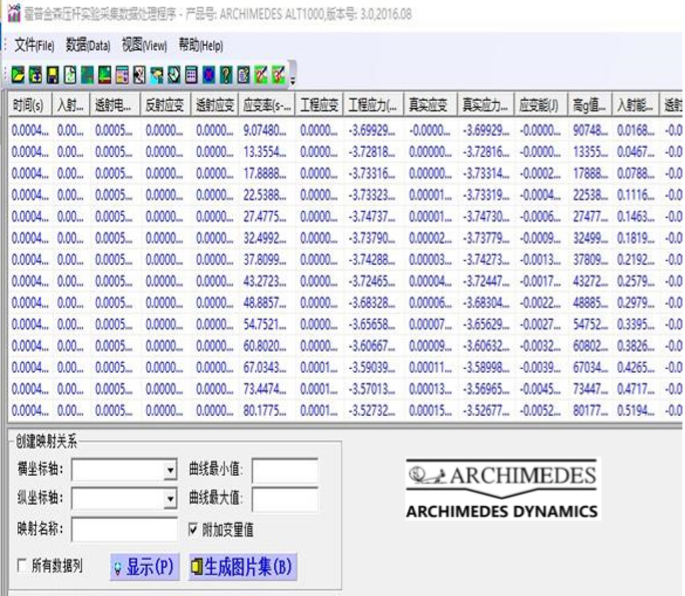

4.1 Operation interface (automatic recognition of calculated waveform)

A data post-processing software system designed and developed by Archimedes Industrial Technology Co., Ltd. Based on the data collected by Hopkinson torsion bar experiment, the software identifies and separates the incident wave and the transmitted wave, and calculates the corresponding parameters such as strain rate, stress, strain energy, incident energy, transmission energy, reflection energy, particle impact velocity and high g value according to the experimental parameters. In addition, the software platform provides the display and editing functions of plane curve, and the original data and calculation data can be displayed and output through graphics and images.

Automatically capture the waveform and calculate the result automatically

It can calculate dynamic shear stress, shear strain, shear strain rate, strain energy, incident energy, transmission energy, reflection energy and other data |